Abstract:

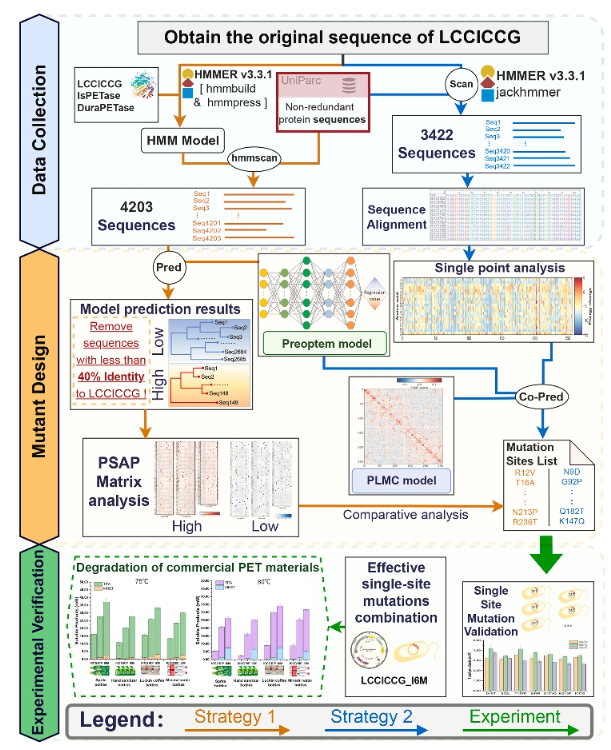

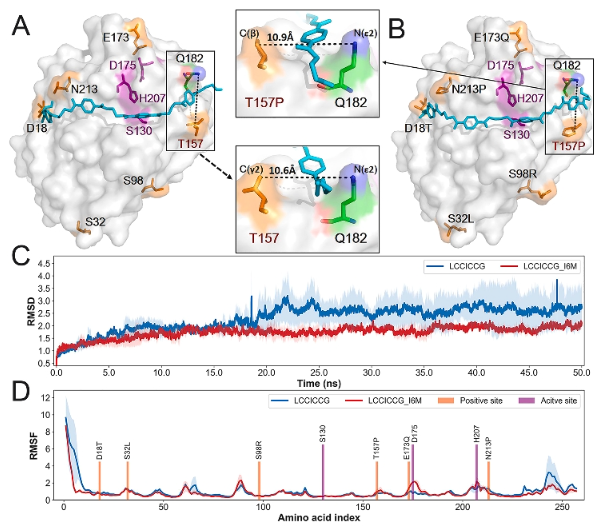

Polyethylene terephthalate (PET)-degrading enzymes represent a promising solution to the plastic pollution. However, PET-degrading enzymes, even thermophilic PETase, can effectively degrade low-crystallinity (∼8%) PETs, but exhibit weak depolymerization of more common, high-crystallinity (30–50%) PETs. Here, based on the thermophilic PETase, LCCICCG, we proposed two strategies for rational redesign of LCCICCG using the machine learning tool, Preoptem, combined with evolutionary analysis. Six single-point mutants (S32L, D18T, S98R, T157P, E173Q, N213P) were obtained that exhibit higher catalytic efficiency towards PET powder than wild-type LCCICCG at 75 °C. Additionally, the optimal temperature for degrading 39.07% crystalline PET increased from 65 °C in the wild-type LCCICCG to between 75 and 80 °C in the LCCICCG_I6M mutant that carries all six single-point mutations. Especially, the LCCICCG_I6M mutant has a significantly higher degradation effect on some commonly used bottle-grade plastic powders at 75–80 °C than that of wild type. The enzymatic digestion of ground 31.30% crystalline PET water bottles by LCCICCG_I6M yielded 31.91 ± 0.99 mM soluble products in 24 h, which was 3.64 times that of LCCICCG (8.77 ± 1.52 mM). Overall, this study provides a feasible route for engineering thermostable enzymes that can degrade high-crystallinity PET plastic.

Key Words:

High crystallinity;;LCCICCG;;PET;;Thermophilic mutant